Modeling of Single- and Multi-Layer Weaves

WeaveGeo®

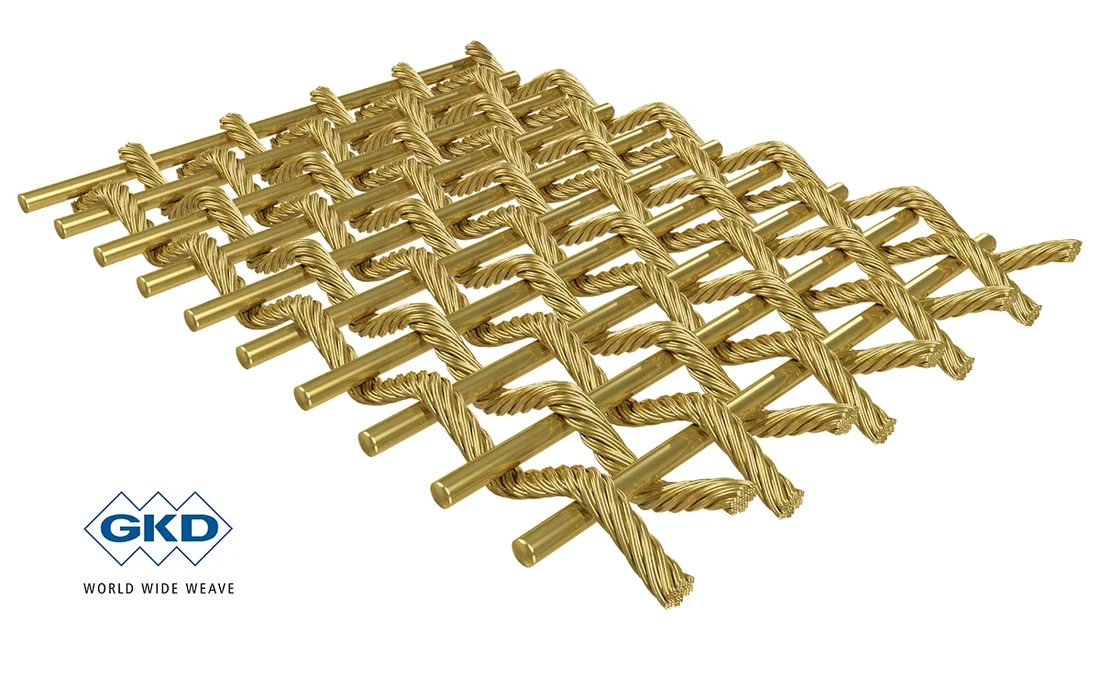

WeaveGeo quickly generates high-fidelity 3D digital models - known as digital twins - of woven materials, including textiles, carbon and glass fiber-reinforced plastics, sand control screens, wire meshes, forming fabrics, and dewatering felts. The process of generating these models starts with a material description, incorporating detailed key parameters such as weaving pattern (binding), layer count, thread or wire diameters, thread or wire shapes, and crimp factor. WeaveGeo is capable of modeling both mono- and multifilament yarns, including ropes and random fiber bundles. Even the reciprocal deformation of weft- and wrap-yarns can be modeled and controlled by assigning a stiffness to materials.

The resulting generated 3D microstructure models, or digital twins, provide an unprecedented level of detail, enabling detailed analyses comparable to those of models obtained from traditional µCT scans. Examples of the analysis capabilities include the computation of the largest through pore or bubble point (with the PoroDict module), the simulation of permeability (with the FlowDict module) and the determination of filtration properties (with the FilterDict module).

The calendering of weaves may be modelled and simulated with the ElastoDict module. It is then possible to analyse the effect that the calendering process has had on properties such as filtration efficiency or flow characteristics.

What distinguishes the digital twins of weaves generated by GeoDict's WeaveGeo from a digitized CT scan is their exceptional versatility. A digital twin based on a statistical model proves immensely powerful for digital material design. It allows different material structures to be explored by digitally manipulating the underlying parameters of the statistical model.

The combination of WeaveGeo and PoroDict is recommended in the ASTM norm E3278-21 international standard as a standard test method for bubble point pressure of woven wire filter cloth (Read more).

WeaveGeo includes multiple options to create woven media.

The Single-Layer Weave command produces plain, twill, and satin weaves in a single layer. Users have full control over weave parameters, including thread or wire pitch and diameter. It supports both standard and Dutch weaves, automatically computing deformations even in extremely tight patterns. Additionally, thread deformations such as broadening and overlap are adjustable. The resulting weaves may be layered to create sand control screens or integrated with fiber models to form dewatering felts.

The Complex Multi-Layer Weave feature generates advanced weaves with intricate bindings. Users define bindings for multi-layer weaves with varying yarn counts per layer. Thread parameters for each position within the weave are fully customizable, including shifts between threads and layers. This flexibility supports the generation of nearly any weave pattern, regardless of complexity.