Energy storage systems are an integral part of the global strategical transition to the use of renewable energy. The battery is ever-present: from cell phones to electric cars. Each single application comes with its own requirements for the battery's properties, which also have an impact on the lifetime of the battery materials.

Particularly with the current transition from using fossil fuels to electromobility, special demands are placed on the materials and storage systems. Innovative solutions are required to meet the demands on energy storage systems in the future, for

- challenging loading profiles

- safety of battery modules

- increasing of the durability

- more environmentally friendly and efficient materials

- reduction of size and weight

- increase of energy capacity

GeoDict - The complete solution

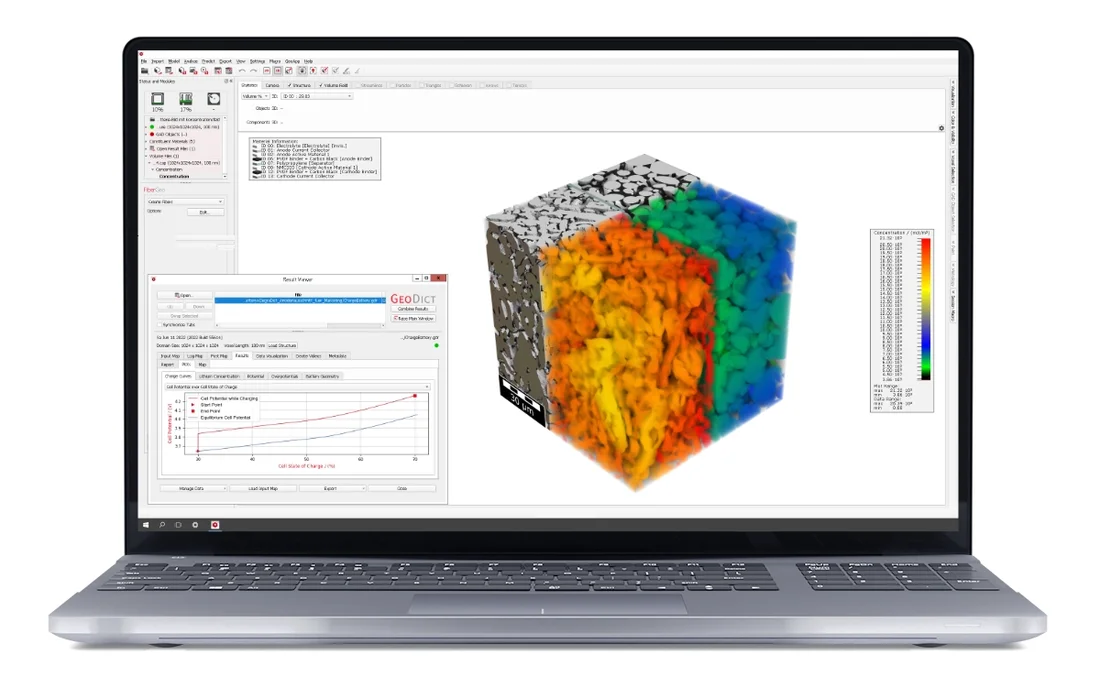

With GeoDict, you gain a comprehensive, sophisticated software package that supports all steps in the digital research and development of battery materials. GeoDict fulfills the highest requirements of a scientific software to solve complex research problems. Thanks to the user-friendly interface it is easy to concentrate on the essentials: the development of tomorrow's battery materials.

Developing innovative materials - simply digitally!

For the optimization of battery materials on the computer, their digital microstructure can originate from 3D imaging such as micro-CT and FIB-SEM, or be modeled directly from scratch using GeoDict's unique material design modules. The performance and characteristics of the battery materials are quickly and precisely determined through the comprehensive analysis and property prediction modules of GeoDict. Thanks to detailed visualization of quantitative simulation data, all details of the simulation results are easily examined.

Simulations reduce testing time and costs

Simulations offer valuable insights into the inner processes and modes of operation of the battery material, which laboratory experiments are unable to provide. This enables you to carry out complementary time-consuming and cost-intensive laboratory tests in a highly targeted manner. The knowledge gained from simulations is essential to directly identify and correct experimental weak points. All without the costly and time-consuming production and testing of prototypes.

Selected Clients of Batteries

to Clients OverviewValuable insights into the battery microstructure and the resulting performance of the battery cell are gained through the coupling of BatteryDict with other GeoDict modules.

By analyzing the electron and ion movements within the active materials (electrolyte and binder), the complex interaction of these transport processes is clearly visualized and quickly and easily evaluated. The further development of battery materials can then be driven forward in a targeted manner based on the findings of these processes.

With the material design modules, the Geo modules, GeoDict offers the possibility of directly implementing these findings in digital material prototypes and then testing them again in a loop with BatteryDict.

BEST, the "Battery and Electrochemistry Simulation Tool", with its solvers BESTmicro and BESTmicroFFT, is used for physics-based battery simulation. BEST has been developed at Fraunhofer ITWM in Kaiserslautern by Dr. Jochen Zausch and his team since 2011. BEST is used to solve non-linear partial differential equations on the voxel grid via simulations and to analyze the transport of electrons and ions within the battery on the microstructure level.

Since the GeoDict 2021 release, the well-known LIR solver has been made available for battery simulations. The new Battery-LIR (BLIR) works similarly to the BEST solver with the Newton method. For the transition conditions between the active material and the electrolyte, the Butler-Volmer conditions are also assumed and solved here.

How fast a battery charges and how high is the capacity of a battery is closely related to the efficiency of the materials of the electrodes. Insights into the path of lithium currents and electron currents within the battery materials are used to identify bottlenecks in the transport paths and overpotentials that lead to lithium plating, for example. In this process, sections of the active material are isolated and not or only with difficulty accessible for the ions, and the capacity of the battery falls short of its potential.

This information is extremely valuable to make well-founded decisions in developing the correct design of battery materials with the desired characteristics and properties.

Battery materials are subjected to constant mechanical processes. The resulting problems, such as narrowing of transport paths and damage to the active material, play a critical role in the performance and durability of the battery. To address these issues, Math2Market participates with the ETH in the publicly funded project SOLVED!. Our approach is to analyze the microstructure of modern NMC cathode and graphite anodes and use the experimental data to validate degradation simulations that calculate local volumetric changes and damage due to lithium deposition. Based on this process, new prototype materials can be designed and optimized.

After the SOLVED! project finishes, GeoDict users in R&D will be able to simulate battery aging during cycling and develop optimized prototype electrodes that have superior performance and lifetime!

Please note that after activating the video, data will be transmitted to YouTube.

More Information

Please note that after activating the video, data will be transmitted to YouTube.

More Information

Please note that after activating the video, data will be transmitted to YouTube.

More Information

The GeoDict Solution for Battery Research & Development

Together with the GeoDict Base, needed for basic functionality, the following GeoDict modules form a package for the Research & Development of battery materials, specifically designed and compiled for the simulation of electrochemical processes.

Module Recommendations

| Image Processing and Image Analysis | ImportGeo-Vol | |||||

| Material Analysis | GrainFind(-AI) | PoroDict + MatDict | ||||

| Modeling & Design | GrainGeo | GrainFind(-AI) | ||||

| Simulation & Prediction | BatteryDict | DiffuDict | ConductoDict | ElastoDict | FlowDict | SatuDict |

Suitable modules depend on the concrete application.