Filters are essential in industry and in everyday life, to preserve machine functionality and for protection against toxic and allergenic substances.

The demands on filter efficiency, selectivity, capacity, and filter lifetime increase constantly and highly specialized solutions are needed for every filtration application. This is due to:

- The complex interplay of material properties of the filter media.

- The arrangement and shape of fibers in the medium.

- The physical and chemical properties of the fluid being filtered.

- The characteristics of the particles in the fluid.

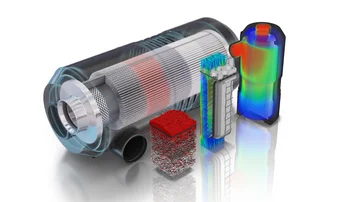

The traditional way of designing, building, and testing filter prototypes is costly in time and resources. Simulations with GeoDict help filter media makers and filter manufacturers understand and productively improve existing filter materials. This approach not only leads to an efficient improvement of materials, but also to the development of completely new filter media and filters. GeoDict covers the entire development workflow and supports you with extensive application-relevant functions.

You can, for example:

- Specify novel filter media characteristics and model filter media matching these specifications.

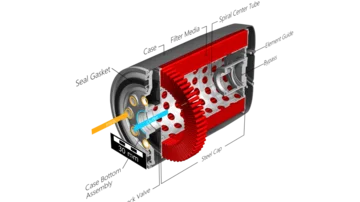

- Determine properties of filter media, such as grammage, largest through pore, multilayers, gradients, binder content, etc.

- Match computed properties to existing media by calibrating.

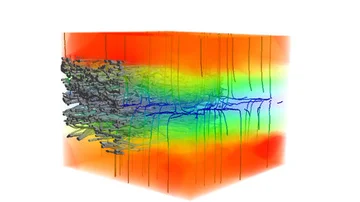

- Determine filtration properties of prototypic digital media, including initial pressure drop, single pass and multi pass filter efficiency, and filter capacity.

- Improve new filter media by varying thickness, fiber diameters, gradient and compression, etc.

Selected Clients of Filtration

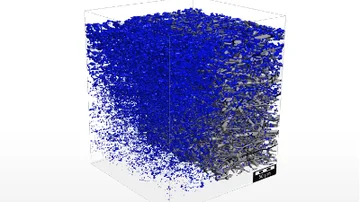

to Clients OverviewNumerous material properties can be analyzed for the simulation of filtration processes in a variety of filter materials, such as nonwoven fabrics, woven fabrics, foams, sintered ceramics, membranes, pleats and support meshes, and wire and plastic meshes:

- Media thickness, fiber diameters, fiber orientation, grammage, pore size distribution, bubble point, percolation path

- Initial pressure drop, pressure drop evolution, initial filter efficiency, fractional efficiencies, filter capacity, filter class, and MPPS

- Particle movement and particle deposition in the filter media, filter clogging behavior, and cake filtration

Workflow to simulate electret filter media

Please note that after activating the video, data will be transmitted to YouTube.

More Information

Generation of cylindrical pleated structures for the digital optimization of filter flow performance

Please note that after activating the video, data will be transmitted to YouTube.

More Information

In addition to GeoDict Base, the GeoDict package includes all necessary modules for the research and development of filter materials.

Module Recommendations

| Image Processing & Image Analysis | ImportGeo-Vol | ||||||

| Characterization & Analysis | GrainFind(-AI) | FiberFind(-AI) | PoroDict + MatDict | ||||

| Modeling & Design | GrainGeo | FiberGeo | WeaveGeo | PleatGeo | |||

| Simulation & Prediction | FilterDict | FlowDict | DiffuDict | ConductoDict | ElastoDict | AddiDict | SatuDict |

Which modules are the best fit for you depends on the nature of your application.