Generation of cylindrical pleated structures for the digital optimization of filter flow performance

Abstract

In recent years, there has been a growing focus on using digital tools to design new filter element geometries, aiming to improve filter performance and satisfy the increasing demands in the filtration industry. The use of Computer-Aided-Design (CAD) has become a key tool, not just at micro levels but also for larger scale simulations, such as analyzing flow and filtration in filter elements and their housings. However, performing systematic simulations on different geometrical setups requires the generation of these structures as CAD individually and importing each sample one by one.

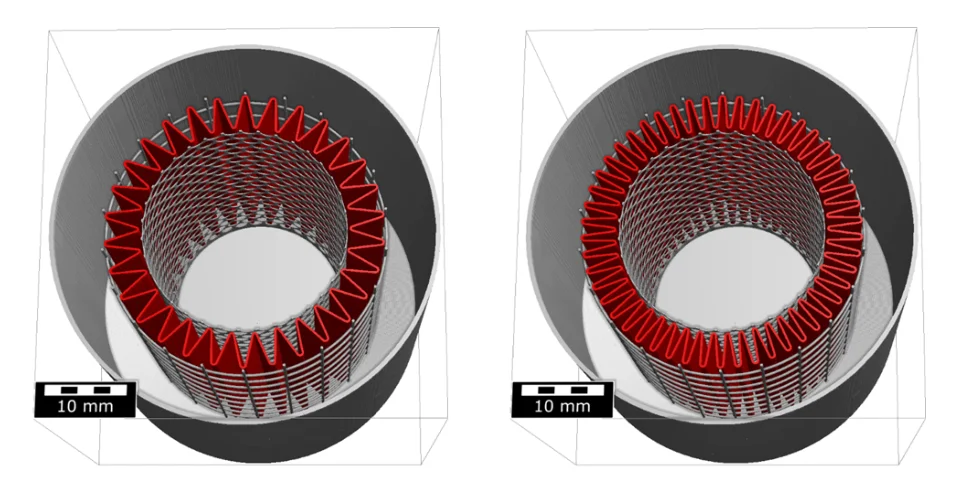

To address this challenge, we have developed a sustainable, digital framework, emphasizing eco-efficiency in design, to create a range of cylindrical pleat structures, varying in pleat count, thickness, and the number of porous layers. This advancement simplifies the creation and digital examination of different cylindrical pleat structures, assessing their impact on pressure drop and other filtration parameters.

This study involves simulating various filter structures with different pleat counts and flow rates to identify the most efficient configuration that minimizes pressure drop, thereby determining the ideal balance between filter area and pleat count. This digital testing of filter designs reduces the need for costly production and physical testing phases, ensuring that only the most promising prototypes are physically tested. Additionally, to enhance efficiency, these systematic simulations can be conducted on cloud platforms, allowing simultaneous runs of various geometries or flow rates.