AI-Based Segmentation of Synthetic Filter Media

Abstract

Artificial intelligence (AI) image processing and analysis tools have recently gained significant interest and have undergone major improvements. Several machine-learning techniques have been used to manipulate and analyze fiber-based images, which in the past required intensive application of image filters. Among these techniques, deep neural networks are exceptionally versatile.

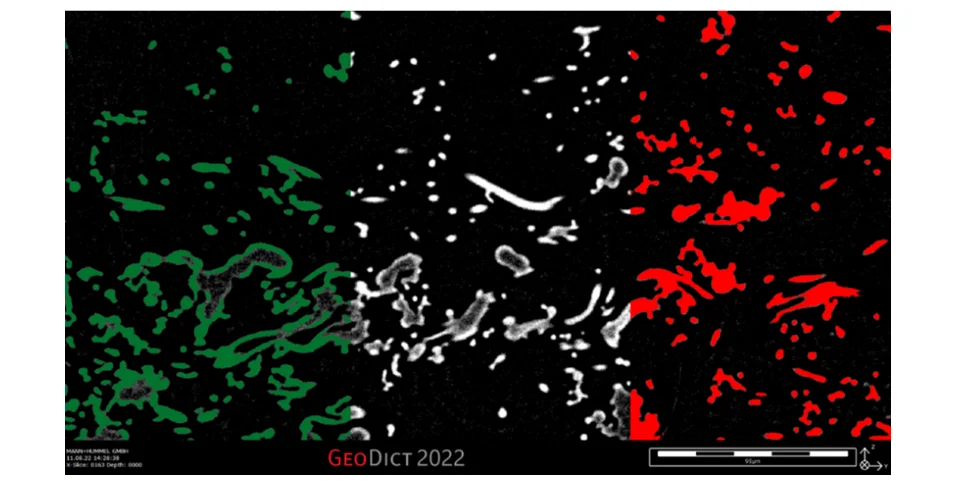

In the last few years, MANN+HUMMEL has gained significant expertise in the segmentation and microstructure characterization of fiber-based filter media [1]. Until recently, mainly manual and OTSU-based threshold methods were used to segment the µCT scans into voxel meshes. These voxel meshes have to be of suitable quality for the subsequent microstructure characterization and microstructure simulation. However, these µCT scans often pose additional challenges. The lower-density fiber material is often hard to distinguish from background noise for filter media with two or more fiber types. Additionally, artifacts can frequently be observed in high-resolution µCT scans (close to 1 µm/Vox), where the fiber core is represented with lower brightness values than the fiber surface. These apparent hollow fiber structures are especially pronounced in meltblown fiber media (Figure 1), which tends to build irregular and clumped material accumulations formed by fibers melting together during manufacturing. If these artifacts are ignored, the resulting segmentation shows hollow fibers and shots that make the voxel mesh unsuitable for microstructure characterization and simulation. Following the segmentation, it is possible with these image processing algorithms to close the hollow structures for standard fibers with round cross-sections, though these image processing show inherent limits for more complex structures. For more complex microstructures with hollow shots, irregular cross-sections, or filter media with multiple fiber types, trying to close the hollow structures using the image processing algorithms can lead to strongly deviating material distributions.

AI segmentation can be used to bypass many of these problems [2]. In order to assess this still relatively young technology's potential realistically, the AI segmentation was tested on problematic µCT-scans of complex fiber structures from various current use cases. The first step is creating training data; parts of the µCT-scan are sparsely labeled manually. The labeled data serves then to train a 3D U-NET [3] implemented in the software GeoDict. By taking into account the 3D context of the image, the fully convolutional deep neural network 3D U-NET offers advantages over 2D U-NET approaches in reliability and prediction bias. The full µCT-scan is then provided to the trained neural network to obtain the final segmentation.

This presentation discusses the results of AI segmentation on different microstructures and compares them with the results of OTSU threshold-based segmentation with subsequent morphological operations. Visual comparison of the resulting voxel meshes of both methods with the µCT scan, as well as the comparison of virtual microstructural properties of both segmentation methods with material testing results, serve to validate the new method and make its advantages comprehensible.

References

[1] Gose, T., Kilian, A., Banzhaf, H., Keller, F., Bernewitz, R., 2019. “Augmented filter media development by virtual prototype optimization“, FILTECH 2019 – F3 - Advanced Filter Media Developments and Manufacturing Methods, Cologne Germany 2019

[2] Arganda-Carreras I., Kaynig V., Rueden C., Eliceiri K., Schindelin J., Cardona A., Seung S., “Trainable Weka Segmentation: a machine learning tool for microscopy pixel classification”, Bioinformatics, Volume 33, Issue 15, 01 August 2017, Pages 2424–2426

[3] Çiçek, Ö., Abdulkadir, A., Lienkamp, S., Brox, T., Ronneberger, O, “3D U-Net: Learning Dense Volumetric Segmentation from Sparse Annotation“, Medical Image Computing and Computer-Assisted Intervention -- MICCAI 2016