Why digital development tools?

Developing solid oral dosage forms and advanced drug delivery systems is complex and resource-intensive.

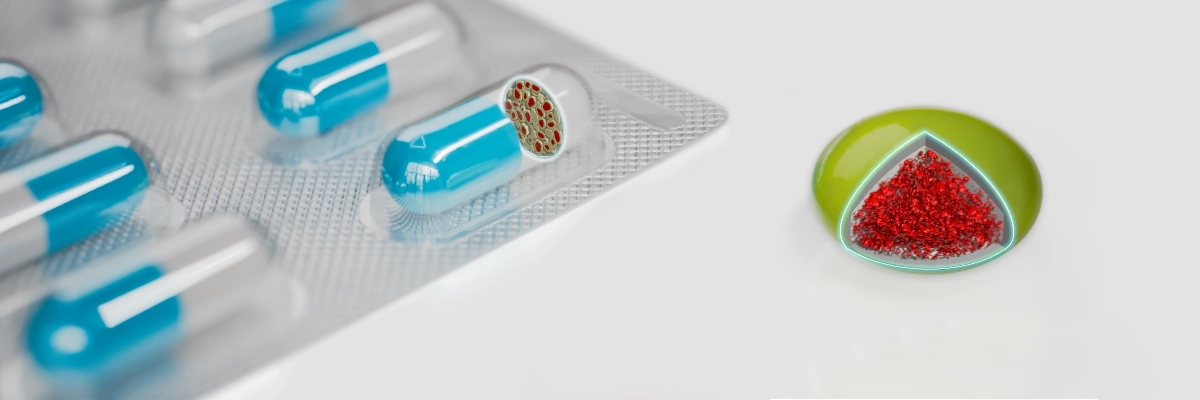

Every formulation step, from powder blending to compaction, coating, and dissolution, involves multiple, interdependent material and process parameters.

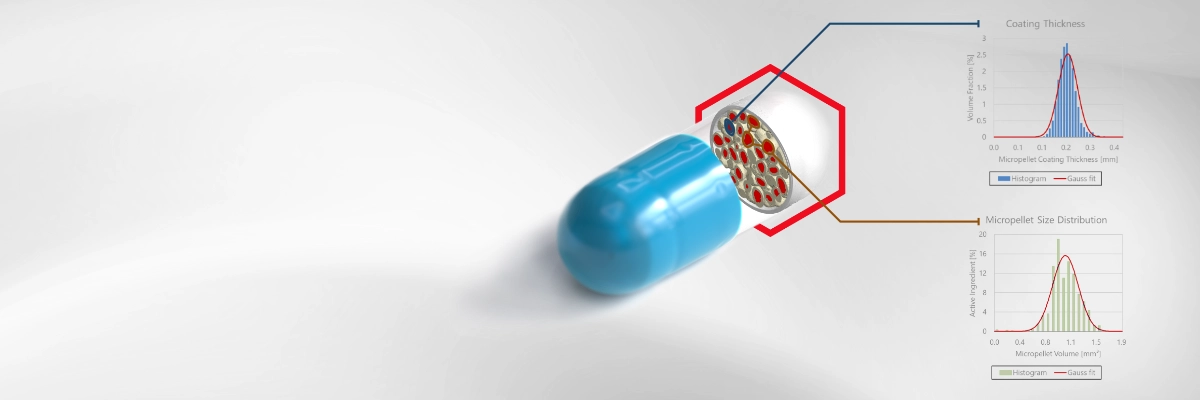

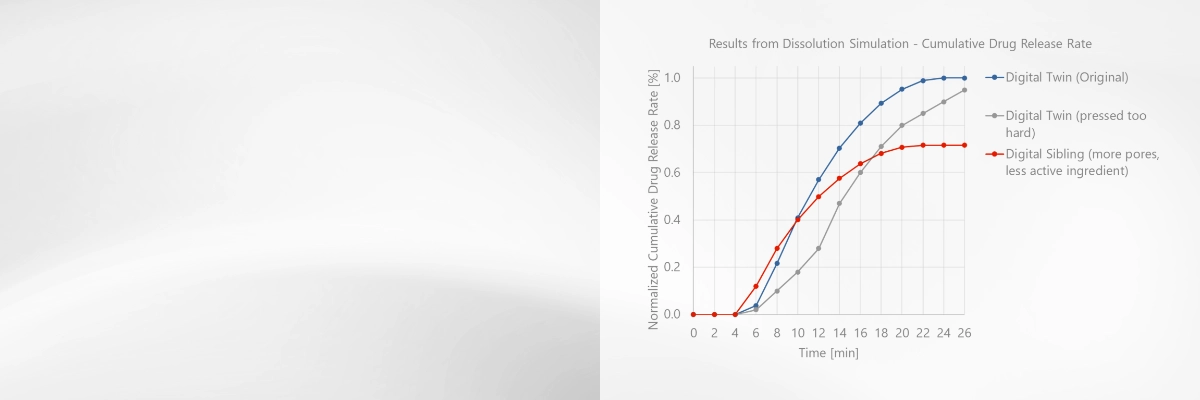

Small variations in particle size, morphology, porosity, or compaction can affect flow, mechanical stability, hardness, and dissolution profile.

Traditional trial-and-error methods require many prototypes, consuming time and resources.

Challenges and their solution with GeoDict:

- Powder characterization: Understand how particle size, shape, and surface properties influence flow, density, and blend homogeneity

- Mixing: Predict compaction behavior and density gradients in tablets or beads.

- Tablet microstructure: Assess mechanical robustness, friability, and crack initiation

- Dissolution and release: Adjust release kinetics by tuning porosity, tortuosity, and coating thickness.

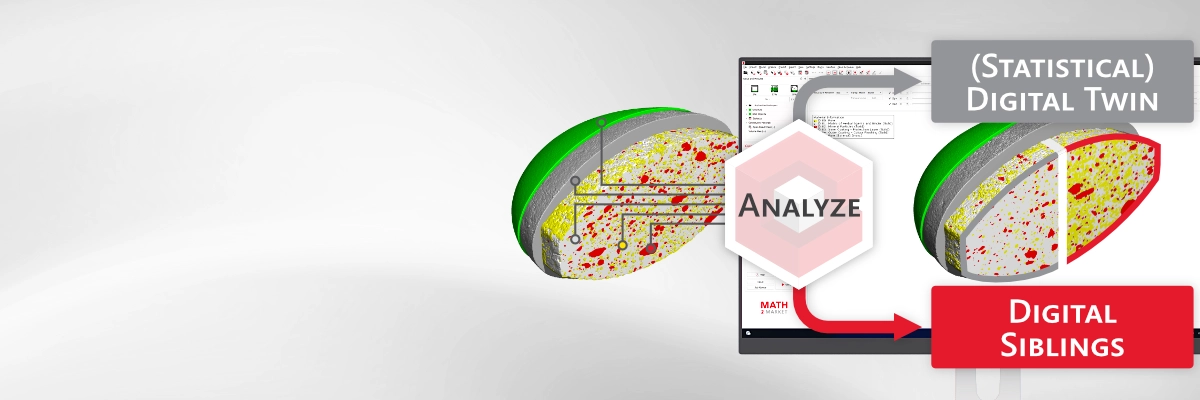

- QbD: Run large parameter studies to identify critical parameters in sensitivity studies.

- Regulatory alignment: Provide transparent, physics-based workflows with full traceability for MIDD strategies.

The GeoDict solution for the digitalization of pharmaceutical formulation

In addition to GeoDict Base, the GeoDict package includes all necessary modules for the research and development of pharmaceutical formulation.

Module recommendations

| Image Processing & Image Analysis | ImportGeo-Vol | ||

| Characterization & Analysis | PoroDict + MatDict | GrainFind-AI | |

| Modeling & Design | GrainGeo | ||

| Simulation & Prediction | FlowDict | DiffuDict | ElastoDict |

Which modules are the best fit for you depends on the nature of your application.