Electrode Design Booster Using a Statistical Digital Twin

Abstract

To successfully master the transition to renewable energies, Li-Ion batteries are needed as part of reliable energy storage systems. To be suited for this challenge, batteries must be fast-charging, durable, sustainable, and cheap to produce while at the same time having a high storage capacity. One piece in this highly demanding puzzle is to improve on the microstructure of the electrodes, i.e., on a length scale of some nanometers to a few hundred micrometers.

On this scale direct experimental approaches are complicated, hard to perform, sometimes even impossible, expensive, and time consuming. To target improvements to batteries on these scales, it is inevitable to use simulations. They back recommendations for the microstructure and help to identify the crucial parameters for performance improvement. We work on a complete commercial software environment called GeoDict that is suitable to perform all the necessary steps.

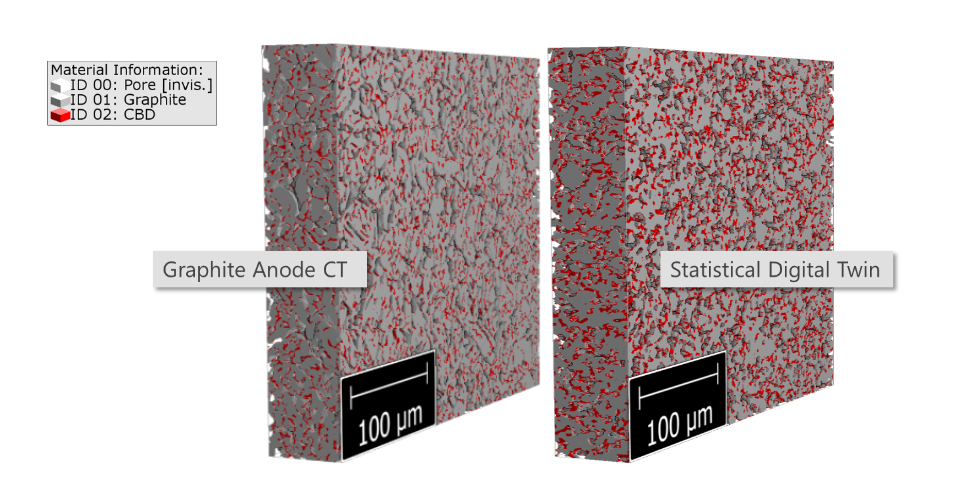

A starting point for improvements of the microstructure is the reliable reproduction of the original material. If the performance parameters match those of the original material, while at the same time the geometrical properties on the microscale match to those of the original material in a statistical sense, we call this model a statistical digital twin.

This talk shows how one can create a digital twin of an electrode material - starting from a scan, it demonstrates all the steps till the validation of the resulting properties.

One starts with an image stack of a cathode material and performs some image processing to enhance the image quality. Next, one segments the material phases and reconstruct the 3D-structure. After that, one calculates statistical properties, like open and closed porosity, tortuosity, or diffusivity, of this imported material. For the creation of the statistical digital twin, one starts with particles with a given shape and size distribution. One specifies the volume fraction of these particles and adapts the shape of the particles. Finally, one adds binder and carbon black with a given contact angle to the structure.

The result is validated by comparing the porosity, tortuosity, and diffusivity of the twin to the same parameters of the originally imported structure. To improve on the result, GeoDict's Python interface allows for scripting an automated iteration of the structure generation.

To show how to ultimately improve batteries, we next alter the microstructure (grain sizes, binder distribution etc.) and describe how these changes effects the crucial parameters, like tortuosity or diffusivity, of the material.

For illustration purposes we will show some results from the BMWK -project “structur.e”, where laser ablation of the CBD - phase, perforation of the electrode and using a graded particle size distribution in the electrode were tested, in order to obtain electrodes suited for fast-charging.

Speaker: Dr.-Ing. Roman Buchheit / Math2Market GmbH