Experimentally validated simulation of strain-induced battery aging

Abstract

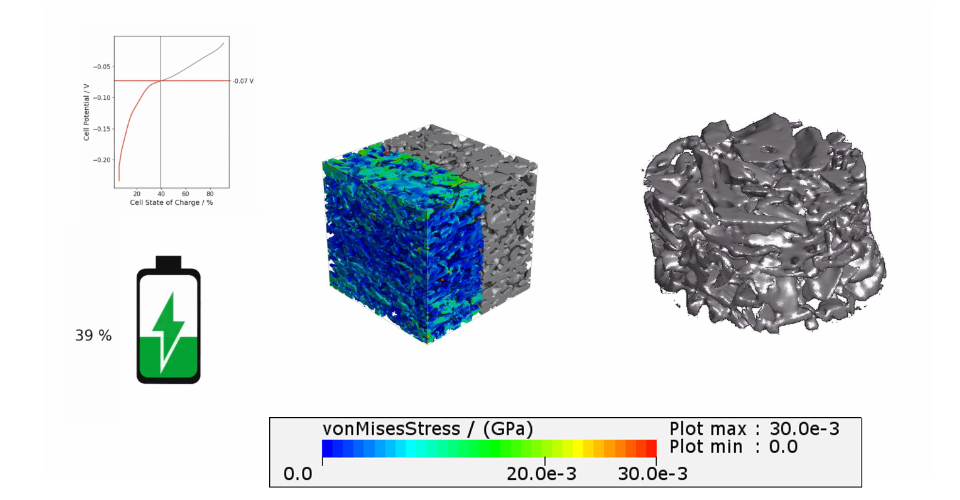

During cycling, volumetric changes of the active material induce stresses on the micro- and macro-scale, leading to cracks and delamination, and deformation of the inactive layers and the casing [1]. The altered microstructure is said to “age” and it suffers from capacity loss and damaging effects like lithium-plating [2]. The quantitative simulation of this battery aging on a microstructural level is now jointly pursued by Math2Market and the MaDE group of Prof. Vanessa Wood (ETH Zürich) in the framework of the EU-project “SOLVED!”.

Our approach is to analyze NMC cathode and graphite anode microstructures via 3D in-vivo tomography and electrochemical characterization [3]. The experimental data is used to validate the degradation simulations in which local volumetric changes and damage, due to lithium intercalation on the microscale, are linked to the local Li-ion concentration in the active material and its mechanical deformation. In a dynamic process, the altered microstructure is considered for each charging and discharging step. In this way, the influence of structural changes on the electronic and ionic transport processes and on the macroscopic performance of the cell is digitally predicted and monitored.

The usage of reliable quantitative simulations allows for the timesaving and streamlined finding of new prototype materials with superior lifetime and performance. This unique workflow represents a new efficient, state-of-the-art approach to digital R&D material design for energy materials in e-mobility and energy storage.

References

[1] Müller, S. et al., 2018, Nature Communications 2018, 9, 2340, DOI: 10.1038/s41467-018-04477-1.

[2] Cabañero, M. A. et al., Electrochimica Acta 2019, 171, 1217–1228, DOI:10.1016/j.energy.2019.01.017.

[3] Pietsch, P. and Wood, V. Annual Rev. Mater. Res., 2017, 47, 451–479, DOI:10.1146/annurev-matsci-070616-123957.

Speaker: Dr. Ilona Glatt / Math2Market GmbH