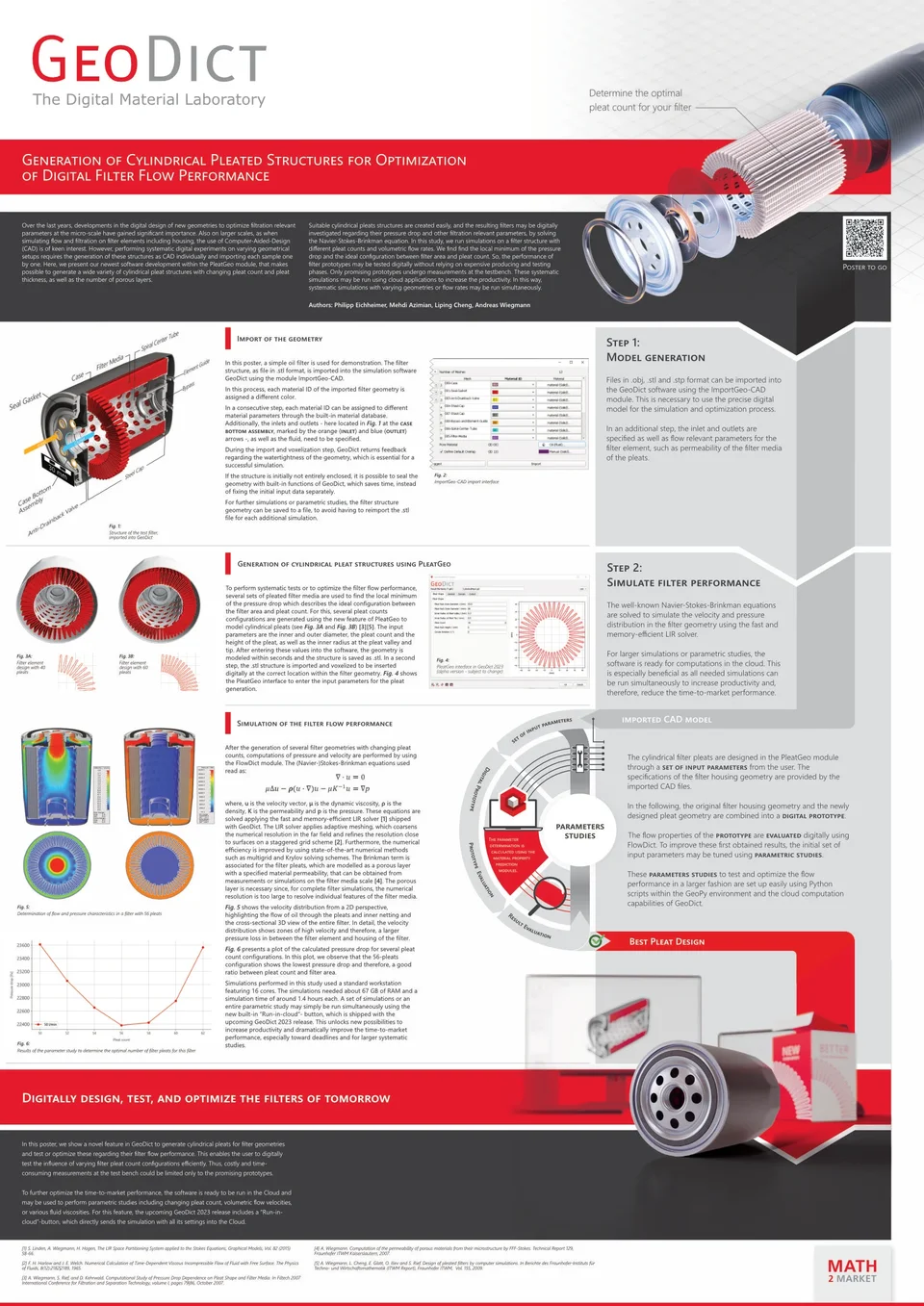

Generation of cylindrical pleated structures for the digital optimization of filter flow performance

Abstract

Over the last years, developments in the design of new geometries to optimize filtration relevant parameters at the micro-scale has gained significant importance. Using Computer-Aided-Design (CAD) is of keen interest also on larger scales, as when simulating flow and filtration on filter elements including housing. However, performing systematic simulations on different geometrical setups requires the generation of these structures as CAD individually and importing each sample one by one.

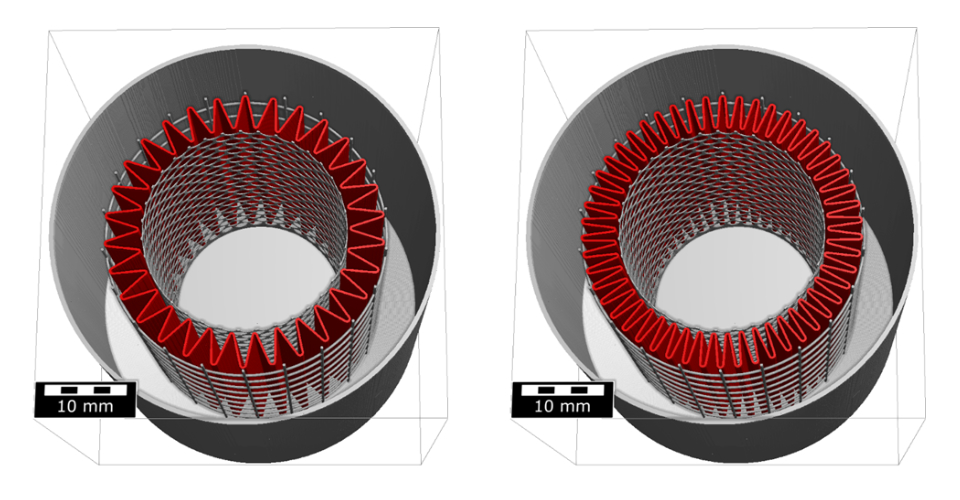

Our work has now advanced to the generation of a variety of cylindrical pleat structures with changing pleat count and pleat thickness, as well as the number of porous layers. This allows to easily create suitable cylindrical pleats structures and digitally investigate different filter structures regarding their pressure drop and filtration relevant parameters.

In this study, we simulate a filter structure with different pleat counts and volumetric flow rates to find the local minimum of the pressure drop, describing the ideal configuration between the filter area and pleat count. This allows to digitally test the performance of given filter prototypes without relying on expensive producing and testing phases. Thus, only promising prototypes undergo measurements at the testbench. To further increase the productivity, these systematic simulations can be run using cloud applications. In this way, the systematic simulations with varying geometries or flow rates can be run simultaneously.