Abstract

The performance level of flat filter media is defined by the three filtration parameters: Dust holding capacity, filtration efficiency, and pressure drop [1]. These parameters directly correlate to the microstructural properties of the nonwoven filter media. Hence, new multilayered filter media are developed, for example, with gradual fiber densities across the media thickness, to increase filtration performance based on filtration simulations and parameter optimizations [2].

To gain the volumetric flow rate required by the application, it is often necessary to pleat the filter media and achieve the needed filter media area in a given design space. The highly anisotropic material behavior of these nonwovens is challenging. At this point in the design process of the new filter media, the microstructure’s effective mechanical properties in the three spatial directions are unknown. The capability to predict these anisotropic mechanical properties of a microstructural design is crucial to assess the new microstructural design’s viability for further processing in the manufacturing of filter elements. Hence, a simulation model to virtually test the microstructural design for tension, compression, and shear in all three spatial directions is needed.

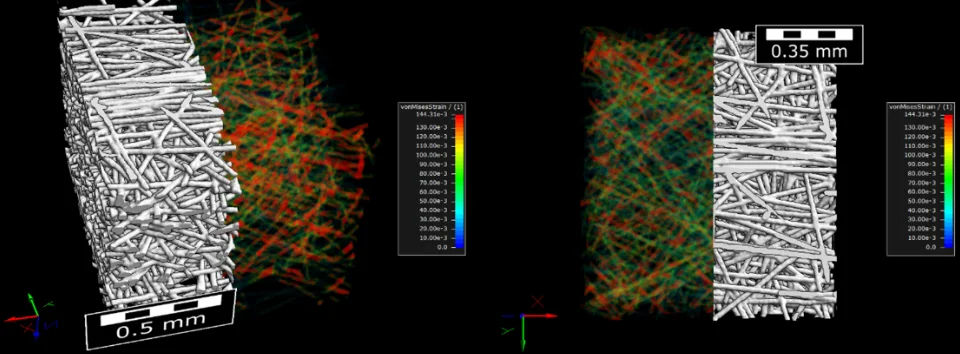

This presentation introduces a microstructural simulation model, using the GeoDict-software package, to predict the three-dimensional elastic-plastic behavior of polymer-based nonwovens. Starting from a representative volume element for the material structure based on micro-computed tomography, we characterize and simulate the material’s deformation behavior when subjected to tension, compression, and shear loads in the machine direction, cross direction, and zdirection. The simulation results are validated using an extensive 3D material testing program. Finally, the dependency of the effective elastic-plastic deformation behavior on a limited number of selected microstructural parameters is discussed. This dependency forms the basis for the usage of digital twins to predict the deformation behavior of virtual microstructure designs.

[1] Klein, G.M., Banzhaf, H., Lehmann, M.J., Heininger, T., 2019. “Filtration in Fahrzeugen: Grundlagen und Beispiele zur Luft- Öl-, Kraftstoff- und Innenraumfiltration“, Die Bibliothek der Technik, Bd.398, Verlag Moderne Industrie, Munich Germany 2019

[2] Gose, T., Kilian, A., Banzhaf, H., Keller, F., Bernewitz, R., 2019. “Augmented filter media development by virtual prototype optimization“, FILTECH 2019 – F3 - Advanced Filter Media Developments and Manufacturing Methods, Cologne Germany 2019