Machine Learning in GeoDict 2019 helps to understand nonwovens

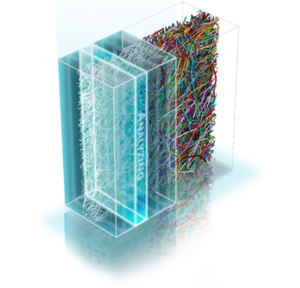

Nonwovens are used in many industries, including fibrous media for filtration, glass- or carbon-fiber reinforced plastics used in mechanical applications, or gas-diffusion layers used in fuel cells. All these materials are vital in modern industry challenges such as green energy and safe production environments.

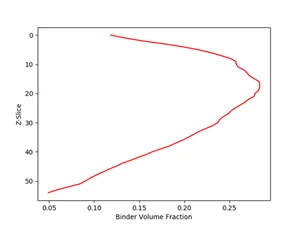

The performance of nonwovens is governed mainly by the spatial distribution, orientation, length, curvature and center line of the individual fibers. For fibrous media with binder, the volume/weight percentage and the spatial distribution of the binder material are also essential. With GeoDict 2019, binder can be segmented from fibers in CT-scans even if they have the same gray values.

Using nonwoven microstructures modelled with GeoDict , a neural network is trained to label binder with artificial 3-D scans, for which the distribution of the binder is known. After the training, the neural network also recognizes the binder in 3-D scans of real nonwovens, which were scanned with µCT or FIB-SEM. The results are high-precision simulations and analyses of the binder distribution in the nonwovens that occur during production.

We apply the same method to identify individual fibers in complex microstructures. Once all fibers are identified, detailed insights into the properties of fibers in a material are obtained. For example, the trajectory of a fiber after deposition in a nonwoven, the length of fibers in glass fiber-reinforced plastic, or local deformations of fibers in weaves.

We are currently expanding the identification capabilities to CT-scans of a variety of materials, such as rocks and foams.