Speaker: Dipl.-Ing. Lennart Heggelmann, Research Assistant, Energy and Thermal Management / Fraunhofer IFAM, Dresden Branch

Calibration of Grey Scale Values for Physically Correct Segmentation of Porous Metallic Transport Layers

Abstract

Porous transport layers play a vital role in hydrogen technology. Current developments focus on porous metallic transport layers made via paper technology with a thickness of down to 200 µm and pore sizes in the range of approximately 5 to 30 µm. This so-called Sintered Porous Metal Paper (SPMP) is made from stainless steel 316L, nickel or titanium. In order to derive property-performance relationships, several morphological and physical parameters of the SPMP are of interest. Digital materials characterization seems to be a well-suited approach to derive parameters such as pore size distribution, specific surface area, and several in-plane and through-plane transport parameters from µCT images.

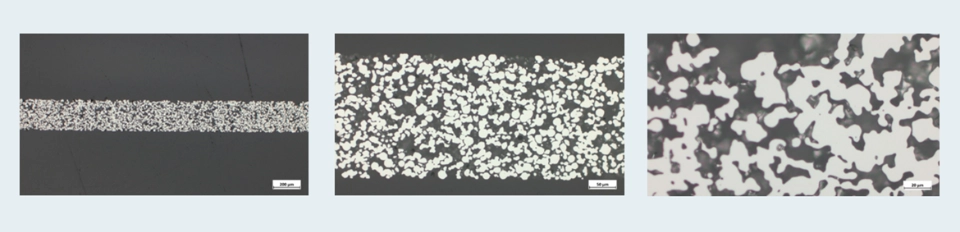

The user-independent determination of a correct grey scale value for the segmentation of the high-resolution µCT scan data is a crucial step in this process. To this end, the grammage (weight per area) of the SPMP is measured and the grey scale value for segmentation is adjusted until the digital representation of the SPMP matches the real grammage. However, we found that this process requires high-quality µCT images. When the µCT images are too noisy or contain too many artefacts, this approach still produces a digital representation of the SPMP with the correct grammage, however, the pore structure may be considerably altered. For instance, it has been observed that small pores vanish while large pores are further enlarged. It is therefore advisable to validate new materials or new µCT settings always by double-checking the resulting digital pore structure after segmentation with metallographic cross sections (Fig. 1). Once it has been verified that the resulting digital pore structure is represented correctly, the new workflow should generate user-independent and physically correct digital representations of porous metallic materials. Currently, a consortium consisting of software and CT hardware providers, providers of porous metallic materials, and end-users of porous metallic materials is aiming at the standardization of such a workflow in order ensure the validity of digital materials characterization of open-porous metallic materials.