Speaker: Sebastian Rehm, Research & Development / Spörl KG Precision Wire Weavers

Development of Composite-Cloths with GeoDict

Abstract

Woven wire meshes are used in a variety of filtration applications due to their excellent filtration properties as well as their high chemical, thermal and mechanical resistance. The demand for finer and finer wire meshes leads to smaller wire diameters, which reduces the mechanical stability of the meshes.

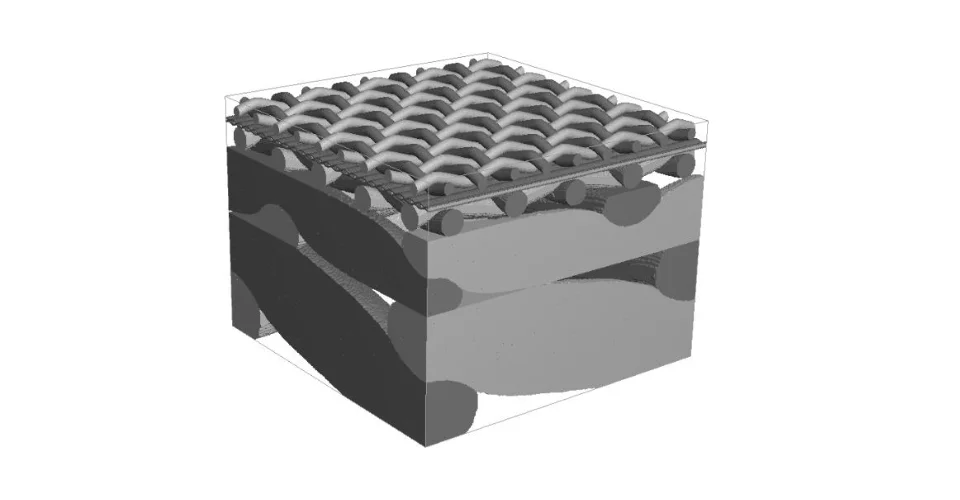

Composite-cloths offer a solution that allows fine meshes to be used in harsh operating conditions. They combine the superior filtration properties of fine meshes with the mechanical stability of coarse meshes. This is realised by sintering the filter layer over its entire surface with one or more coarser supporting, protection and drainage layers in a high-temperature sintering process. The selection of different layers determines properties such as filtration performance, pressure loss and mechanical stability.

The production of composite-cloths is time-consuming and expensive due to the sintering process, which is why they are developed digitally with GeoDict. First, the single layers are modelled. The pressure loss is calculated with the GeoDict module FlowDict and the results are validated against experimental data. Prior to the sintering process, the single layers of mesh are calendered. This process is simulated with the GeoDict module ElastoDict. The single mesh layers are digitally assembled into a composite-cloth. The pressure loss of the composite-cloth is calculated and again validated against experimental data.

The digital development process allows the optimisation of composite-cloths regarding pressure loss using a newly developed layer structure. Furthermore, newly developed filter layers can be tested in composite-cloths without the expensive and time-consuming sintering process.