Digital Materials Design (DMD) is a modern approach for model-based material optimization and can be applied to optimize electrodes for solid oxide fuel cells (SOFC). Therefore a combination of stochastic microstructure modelling, virtual testing of 3D microstructures and a multiphysics electrode model provides a good basis for data driven microstructure optimization. The software GeoDict enables studying hundreds of different microstructures in an automated workflow for the generation, simulation and characterization of virtual microstructures.

Generation of virtual three-phase Structures based on Gaussian Random Fields: An important Option for Digital Materials Design of Solid Oxide Fuel Cell Electrodes

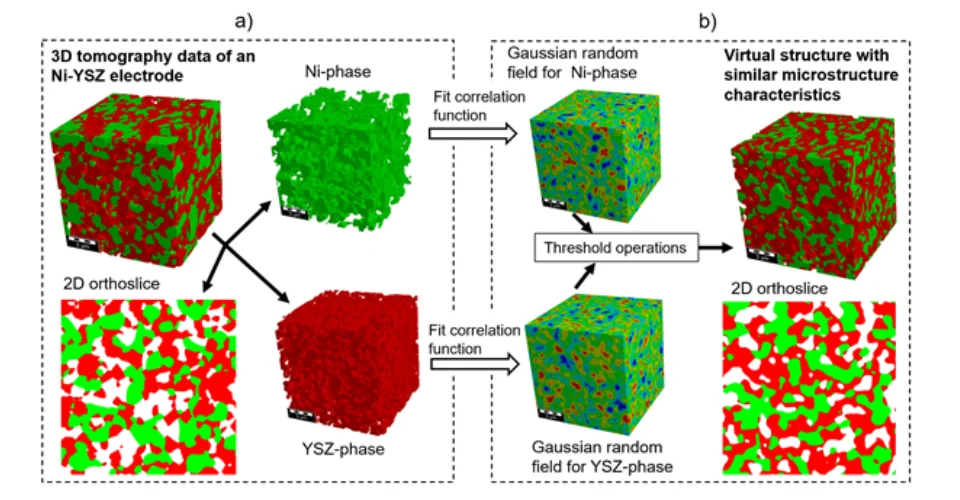

In this context, an appropriate structure generator is needed, which enables efficient creation of virtual microstructures with realistic properties by means of stochastic parameter variations. SOFC electrodes are typically three phase systems with a pore space and two solid phases like the common Ni-YSZ anodes. Normally, they are strongly sintered, resulting in continuous phase networks and can hardly be represented by sphere or particle packing methods. Those generally yield in a microstructure that keeps the geometry of the initial spheres/particles. The structure generation based on Gaussian random fields is an alternative approach, which provides continuous phase networks from the outset. This approach was introduced for the application of SOFC electrodes by Moussaoui et al [1].

In order to obtain a closed workflow with microstructure generation and characterization, we have now implemented the approach in GeoDict. Thereby, two truncated gaussian random fields are constructed, one for each solid phase. The gaussian random fields are characterized by their covariance function, and can be fitted to covariance functions of 3D tomographs of real samples. Using appropriate threshold operations, the solid volume fractions and the wetting behaviour of the phases can be adjusted. The remaining space is considered as the pore phase. Therewith, many different microstructures can be deduced from one set of two gaussian random fields.

The resulting virtual microstructures can be characterized by numerical transport simulations and morphological analysis using GeoDict. Therewith, it can be ensured, that the virtual structure shows the right characteristics regarding the relevant physical effects. The most relevant microstructure parameters for the common Ni-YSZ fuel electrodes are the relative conductivities of both phases, the specific length of the three phase boundaries and the gas transport in the pore phase. The last one is governed by bulk and Knudsen diffusion.

Using a multiphysics electrode model, the microstructure properties can be linked to the cell performance. If an appropriate digital twin is found, the microstructure parameters can be varied in a realistic way. However, long computing times and the lack of available computational resources usually put strong limitations for extensive parameter sweeps. With the GeoDict Cloud, hundreds of virtual microstructures can be studied in parallel in a very short time using massive simultaneous cloud computing (MSCC) powered by KaleidoSim. The statistical analysis of these results leads to new design guidelines for electrodes with improved properties.

References

[1] H. Moussaoui et al., “Stochastic geometrical modeling of solid oxide cells electrodes validated on 3D reconstructions,” Comput. Mater. Sci., vol. 143, pp. 262–276, 2018, https://doi.org/10.1016/j.commatsci.2017.11.015

[2] L. Holzer, O. Pecho, T. Hocker, B. Iwanschitz, A. Mai. (2020). FIB-tomography data of Ni-YSZ anodes for Solid Oxide Fuel Cells (SOFC): Comparison of pristine and degraded materials (before/after redox cycling) (Version 1) [3_Rx36_Segmented]. Zenodo. https://doi.org/10.5281/zenodo.4056538